MULTIDEC®-MICRO TOOLS

THE DRILLING AND MILLING SOLUTIONS FOR YOUR MICRO-MACHINING

Economical, reliable and precise, even for difficult-to-machine materials.

U-DRILL

Solid carbide micro tools, spot drills and twist drills

The “u-drill” range includes various spot drills and twist drills.

Overview:

-

90° and 120° NC spot drills from Ø 1 to 6 mm

-

Solid carbide twist drills from Ø 0.3 to 1 mm in 0.05 mm steps available

from Ø 1 in 0.1 mm steps up to Ø 3 mm available, in 3×d1 length with reinforced shank, self-centering shape -

Solid carbide twist drill from Ø 0.1 to 0.29 mm in 0.01 mm steps available

7×d1 version with reinforced shank, self-centering shape -

Solid carbide twist drill from Ø 0.3 to 2.00 mm in 0.01 mm steps available

from Ø 2.05 to 3.00 mm in 0.05 mm steps available, 5–8×d1 length version with reinforced shank, self-centering shape

► TO THE NC SPOT DRILLS

► TO THE TWIST DRILLS

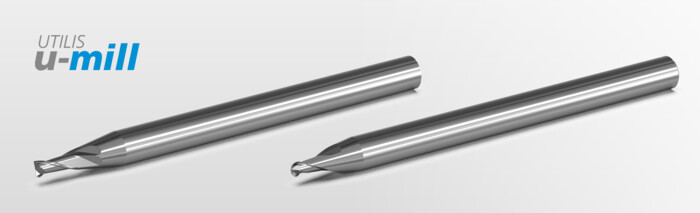

U-MILL

Solid carbide micro tools, end mills and ball nose end mills

Under the line “u-mill” you can find end mills and ball nose end mills.

Overview:

-

Solid carbide end mills from Ø 0.2 to 3.00 mm with center cut, as 2 and 3 teeth

-

Solid carbide ball nose end mills from Ø 0.3 to 3.00 mm, 0.75×d1 and 3×d1 length with center cut and without tooth pitch

► TO THE END MILLS

► TO THE BALL NOSE END MILLS

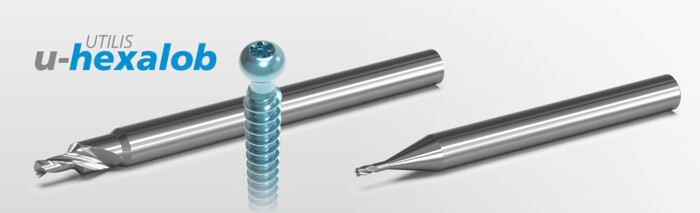

U-HEXALOB

Solid carbide micro tools for milling TORX® contours

The micro tools of the “u-hexalob” line are specially adapted to the individual TORX® depths and offer optimised geometry for machining stainless steel and titanium.

Overview:

-

Solid carbide pilot drills from Ø 0.90 to 3.90 mm for spotting and centering with a 120° chamfer

-

Solid carbide end mills with three teeth, from Ø 0.20 to 0.30 mm, usable length of 3.5×d1 and 5×d1 perfectly suited for milling a TORX® form

-

Solid carbide end mills with four teeth, from Ø 0.40 to 1.00 mm, usable length 3.5×d1 and 5×d1 perfectly suited for milling a TORX® form

Festim DZEMAILI

Festim DZEMAILI